TANGUB CITY — The P7.38-billion Panguil Bay Bridge in Northern Mindanao is moving on schedule with bored piles for the piers and abutments almost done, despite the two-year pandemic lull.

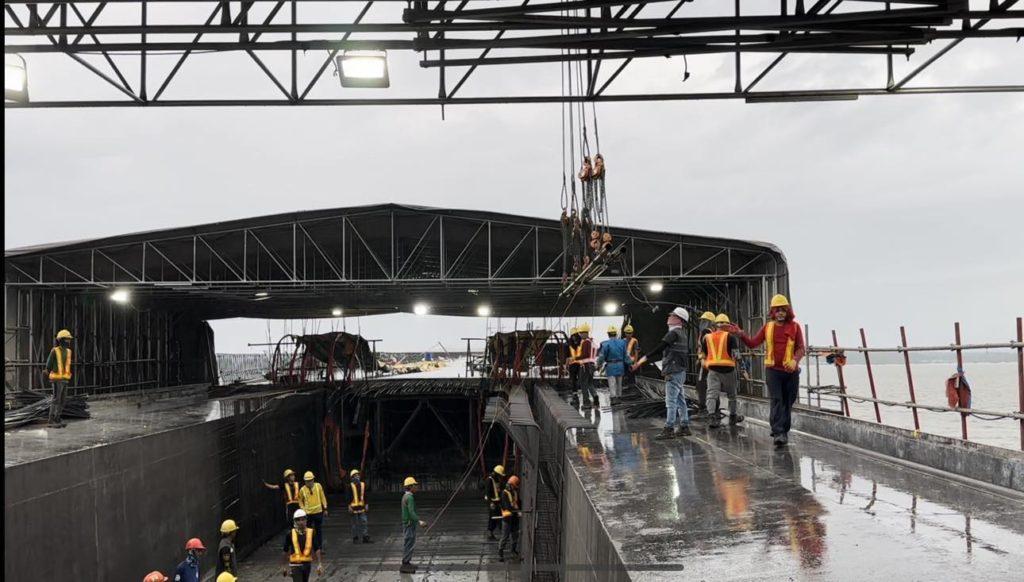

The ILM Korean technology makes the difference in the construction, said Project Management Office manager Engr. Marlon Galerio of the Department of Public Works and Highways (DPWH) said “The work is 24/7 rain or shine because the contractor is using ILM or Incremental Launch Method, the technology being implemented here and this is the first in the country”

The project is a joint venture with Korean contractor Namkwang-Kukdong-Gumwang.

Galerio said the 3.169-kilometer inter-island two way bridge with two hardened pavement, is now 70-percent complete and expected to be completed during the year end.

The bridge project requires 54 bored piles for the 32 piers, two (2) abutments at Tangub City, Misamis Occidental and Tubod, Lanao Del Norte, and two (2) pylons of the main bridge.

Korean Engineer Tae Hwan Cho told Newsline “At first we train the local workers how to adopt our technology because this is the first in the Philippines, with the ILM technology, the work for ten (10) days can be done in a day because we work 24/7 rain or shine, we have a concrete oven to process the drying and curing of the cement for 38-hours to ensure it does not scour and the quality of the cement is preserved.’

The project as two (2) land and sea-based batching plants on site, each with supply capacity of 120 cubic meter of ready-mixed concrete per hour.

As designed, Galerio explained with ILM “From steel fabrication of the bottom slab to the top slab pouring and oven curing takes more than 38-hours, after which the slab will be placed in a steering launch then lift and push to the ready structure.”

But the inclement weather sometimes delay the delivery of aggregates and other materials which come other towns, Cho explained “It there is delay it is just about 2.2 percent slippage but it is very manageable.”

The DPWH in a statement said, each of the completed bored piles are subjected to cross hole sonic logging test after 7 to 14 days of concrete pouring in order to ensure quality by assessing the integrity of materials used in the cast-in-site pile as well as load test to determine the safety factor.

A three (3) meter diameter bored piles is made by producing bore holes with the use of reverse circulation drilling machines on barges followed by the launching of 23 millimeter thick permanent steel casing using revolving crane barges and vibro pile hammers, and until final concrete pouring.

Misamis Occidental Governor Henry S. Oaminal said “The project will benefit the Misamisnon (people of Misamis) because this will connect us to Tubod Lanao del Norte and the landing is here in Tangub City, Misamis Occidental, the travel of goods and movement of people will be easier because the travel time will be reduced from 3-hours to only seven (7) minutes. It will benefit the people from other regions and other areas of Mindanao and of the country who want to visit our province.”

If the project will be operational, the economy and tourism industries will be livelier and the investors will have easy access to the province, Oaminal explained.

During his first term of office as the Representative of the Second District of Misamis Occidental, Oaminal said he requested the national government to revisit the project which was not realized due to budget contraints but “In 2016, I asked the national officials to revisit the project and give to us the project we deserved, and a year after the loan agreement was signed between the Philippine Government and the South Korea Government through the Economic Development Fund (EDF).”

The project is funded by a loan agreement between the Philippine government and Korean Export Import Bank.

“This project is dedicated to the people of Misamis Occidental and the people of Mindanao, this is our gateway to economic and tourism development, Oaminal stressed.-Editha Z. Caduaya

.

.